Polyvinyl chloride (PVC) is one of the most commonly used thermoplastic polymers in the world (after several more widely used plastics, such as PET and PP). It is naturally white and very brittle (before plasticizers are added) plastic. PVC has a longer history than most plastics first synthesized in 1872 and produced by the B.F. Goodrich Company in 1920. By contrast, many other common plastics were first synthesized and only became commercially viable in the 1940s and 1950s. It is most commonly used in construction, but is also used in signage, healthcare applications and fibers used in clothing.

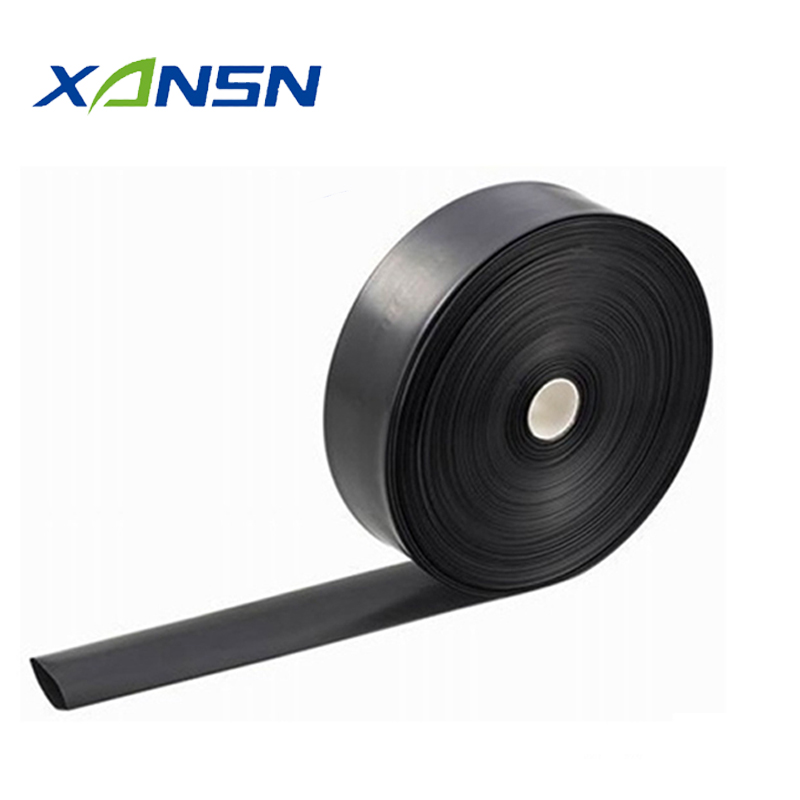

PVC comes in two general forms, a rigid or unplasticized polymer (RPVC or uPVC) and a flexible plastic. Flexible, plasticized or regular PVC is softer and more flexible than uPVC due to the addition of plasticizers such as phthalates. Flexible PVC is commonly used for electrical wiring insulation in buildings or flooring in homes, hospitals, schools and other environments (sterile environments are preferred), and in some cases as a substitute for rubber. Rigid PVC is also used in construction as a conduit for pipes and siding, and is often referred to as "vinyl" in the United States. PVC pipes are usually referred to by their "schedule" (for example, Schedule 40 or Schedule 80). The main differences between schedules include walls. Some of the most important properties of PVC plastics include: relatively low price, environmental degradation (as well as resistance to chemicals and alkalis), high hardness and excellent tensile strength in the case of rigid PVC. It is widely available, commonly used and easy to recycle (classified by resin identification code "3").

What is PVC used for?

The diversity of PVC applications challenges the imagination. In daily life, they are everywhere. PVC can be used for everything from building profiles to medical devices, from roofing membranes to credit cards and children.Toys can be placed in pipes for water and gas. Few other materials are versatile or capable of meeting such demanding specifications. In this way, PVC fosters creativity and innovation, offering new possibilities every day.

Why is polyvinyl chloride (PVC) often used?

Rigid PVC especially for plastics has a high density, making it very hard and usually very strong. It is also easy to obtain and very economical, which, combined with the durable properties of most plastics, makes it a convenient choice for many industrial applications, such as construction.